Waste paper recycling egg tray production project Analysis Report

Waste paper recycling paper pulp molding machine professional manufacturer

Egg tray production project investment report can help you to familiar with the costs, returns, risks of waste paper recycling paper pulp trays production project. We Qingdao Perfect Equipment assisted more than 45 countries customers set up 130+ successful egg tray fruit packing trays tableware trays production plants around the world, like Russia, America, Colombia, Mexico, Venezuela, Argentina, Ecuador, India, Philippines, Malaysia, Indonesia, Saudi Arabia, Egypt, Morocco, Spain, Turkey, Yemen, UAE, Nigeria, Pakistan, Kazakhstan, Dominica, Bolivia, etc. Based on the rich production and installation service experience, you will enjoy professional one stop service for your paper fiber pulp packing trays production project from machines production to the installation and running of the egg tray production line.

The working progress video of automatic egg box tray production line with metal drying oven:

6000 pieces per hour automatic egg tray production line with metal dryer

A. What is the Paper Egg Tray Molding Machine’s working principle?

The waste paper OCC is feed into the pulper and water is supplying to the pulp storage tank. The pulp in the pulp storage tank is stirred evenly by the mixer and pumped to the pulp supply tank. The pulp in the pulp supply tank is stirred to a certain concentration, the stirred fiber pulp be supplied to the egg tray molding machine, molding machine form the paper pulp egg trays under the vacuum pump’s assistant. The conveyor belt, the conveyor belt passes through the drying hole, dries the egg tray, and finally collects and packs it. In addition, the unused water in the molding machine can be pumped to the return tank through the vacuum pump, and the return tank can deliver water to the pulper and the pulp storage tank, so that the water can be recycled.

Raw material: OCC Waste paper, including old books, newspapers, paper cartons, offcuts, etc.

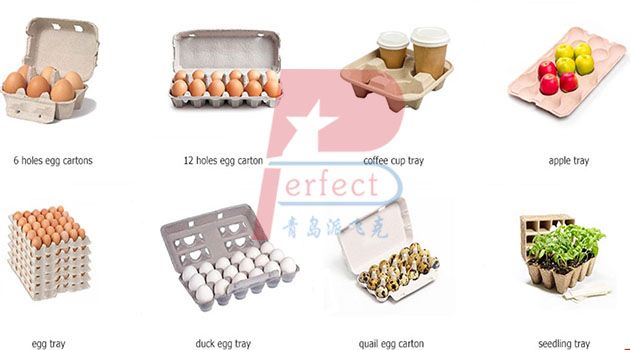

Output Products: 30-cavity egg trays, 12-cavity egg boxes, 6-cavity egg cartons, apple trays, seedling trays, shoe trays, cup holders, bottle trays, etc.

B. Profit Analysis of Egg Tray Production Investment

The main cost of egg tray production includes raw materials cost (paper), water, labor force cost, fuel cost, depreciation and maintenance costs, etc. While the input is mainly the income of selling the trays. Below is a profit analysis based on our F1000 Small egg tray machine.

F1000 Small Egg Tray Machine Profit Analysis | ||||

Daily Raw Material Consumption (10 hours/d) | ||||

Items | Consumption | Unit Price | Cost/d | |

Waste Paper | 85kg*10 | $ 25/t | $21.25 | |

Water | 255kg*10 | $ 2.43/t | $6.19 | |

Workers | 3 workers/d*10 | $2.53/h | $75.9 | |

Natural Gas | 32kg*10 | $4.43/t | $1.42 | |

Power | 34kW*10 | $0.12 / kWh | $40.8 | |

Depreciation | $10/d | |||

Other Cost | $10/d | |||

Total Cost | $165.56 | |||

Output | Unit Price | Income | ||

1,000 pcs/h *10 | 0.05/piece | $500/d | ||

Net Income | $334.44/d | |||

Monthly Income (25 days/m) | $8361/month | |||

Annual Income | $100,332/year | |||

Remark: The data here do not contain the buying cost of the egg tray machine, space cost, construction cost, wear parts cost, etc. And the cost and selling price will be different in different areas. But it is obvious that it is profitable to invest in an egg tray machine. The related cost are calculated as China local cost level.

C. The Promising Future of Paper Egg Tray Production

With the ban on plastic products in more countries, pulp molded products are getting popular due to its biodegradability and portability; The egg tray production process is pollution-free. More than that, it recycles waste paper into something useful. It is eco-friendly; There are more and mode designs of pulp trays to meet the different requirements of customers; Poultry farmers can buy an egg tray machine to make their egg production more profitable.

D. Preparation for Egg Tray Production Project Investment

In order to start your egg tray or paper pulp products production project efficiently, you need to do below preliminary work

1. Do Market Research

You need to know what pulp molded products are in great demand in your local market, and how many trays you will make to sell. For example, if you have a poultry farm with 300,000 chickens and you make trays for your farm only, one set F1000 Small egg tray machine can meet with your needs well already. In addition, make clear the locally available fuels. The dryer can be designed with fuel sources.

2. Prepare Your Budget

Our small egg tray making machine cost is lower to USD9000/Set. Generally, the automatic rotary drum egg tray molding machine will be more expensive. Besides that, you also need to calculate the freight cost for the machines, land space, workers, fuels, electricity, etc. So you need to put all these factors into consideration.

3. Where to Get the Raw Materials?

You need a reliable supply of waste paper old boxes, and more old books or newspapers are better. The carton box and cardboard manufacturers, paper factories, and other paper products factories which will output waste paper and cardboards will be a good choice for your raw material supplying. So you’d better know the waste paper price, which will directly influence your profits.

4. Find a land for Your Factory

The egg tray machine itself does not need big space. But you also need space for raw materials and end products storage, office space, for pulp making and drying. For example, the brick drying line is single-layer. So it requires at least 45 meters in length. If you don’t have enough space, you need a multilayer metal drying room instead. In addition, your egg tray factory should be convenient for transportation.

5. Familiar with Your Local Government Policy about the waste paper recycling industry.

There is no water pollution and no air pollution during the production process. It may be helpful for you to get the certificates. But you need to know the related policy in your area. For example, there is a ban on plastic products, which will make the waste paper recycling industry more promising. And if there is special policy for the industry noise or not nearby your area. Please make sure that you already get all the required licenses from your local government before start the project.

6. Chose and Cooperate With Reliable Machine Supplier

There are numerous egg tray machine manufacturers and suppliers on the market, especially in China and India. You need to choose the one who offers quality machines and services, we Qing Dao Perfect Equipment have 130+ successful cases all over the world, and we are confident to provide you the best and professional solution with the most competitive quotation and best after sales service. If you want a customized egg tray manufacturing project report, please contact us freely.

For more information about QINGDAO PERFECT EQUIPMENT egg tray making machines:

China egg tray making machine producer

Automatic Industrial Paper Pulp Packing Egg Trays Making Machine Popular in South America

Popular in Russia automatic paper pulp molded egg tray making machine