Capacity: 2000-2500 pieces/hour or 2500-3000 pieces/hour

Project case working video in Africa

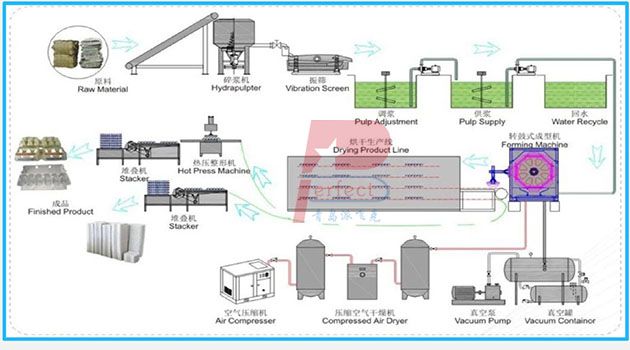

Consists of:

Pulping system, 4 faces rotary egg tray making machine, air compressor, vacuum pump, 12 pieces egg tray molds or 16 pieces egg tray molds, 6 layers metal dryer

Usage:

Use waste paper, old carton box to produce egg tray, you can also use it to produce other paper trays like shoe tree, egg box tray, wine tray by changing molds (shoe tree, egg box tray or wine tray need die cutting machine and molds to cut edges after drying)

Working theory:

Feed the cleaned raw waste paper and old cardboards into the hydrapulper to recycle into paper pulp, then the pulp will be supplied to the molding machine by the pulp pumps, and egg tray forming machine will do vacuum absorption to form the egg tray under the vacuum tank and air compressor’s assistance, then labor taking the finished egg tray onto drying frames and pallets for sunshine drying or match single or multi-layer metal dryer for automatic drying ( diesel oil or natural gas as fuel); Brick dryer use coal without smoke can be designed also.

Automatic egg tray production line with brick drying oven working video:

Brick dryer oven automatic egg tray production line 2800 pieces per hour

Working flow of automatic egg box tray production machine with metal dryer

Qingdao Perfect Equipment Egg Tray Machine

Qingdao Perfect Equipment Auto Egg Tray Machine Spain

If you have any questions, feedback or comments, please fill out the form below and we will reply you back as soon as possible.